Product applicationYour current position:Home > application > New Low-Voltage Ceiling Fans Save a Lot of Energy Over Traditional ACIM-Based Fan Designs

New Low-Voltage Ceiling Fans Save a Lot of Energy Over Traditional ACIM-Based Fan Designs

| Source: Baoxingwei technology | Release time:2024-03-13 15:38 | Number of views:157 |

Name:New Low-Voltage Ceiling Fans Save a Lot of Energy Over Traditional ACIM-Based Fan Designs

Detailed introduction:

Optimize Your Fan Solution

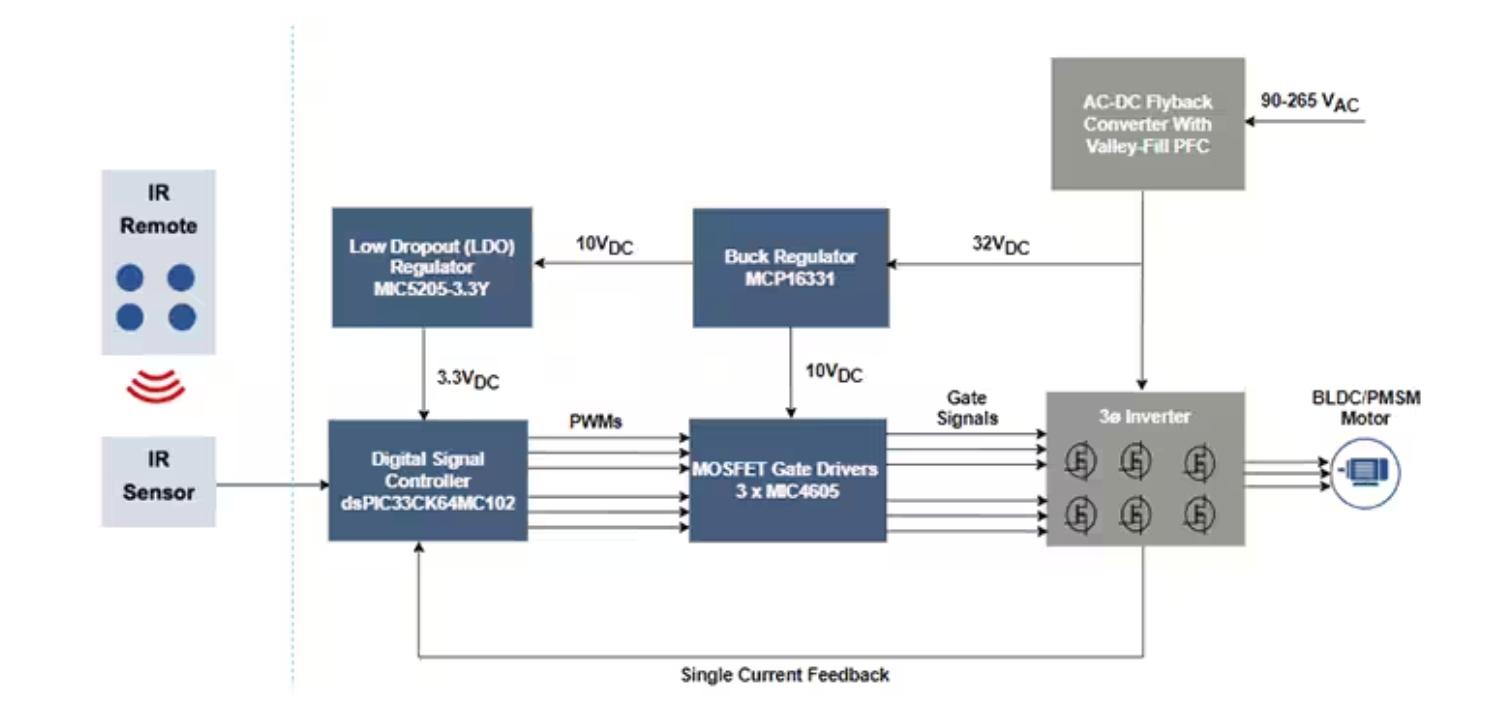

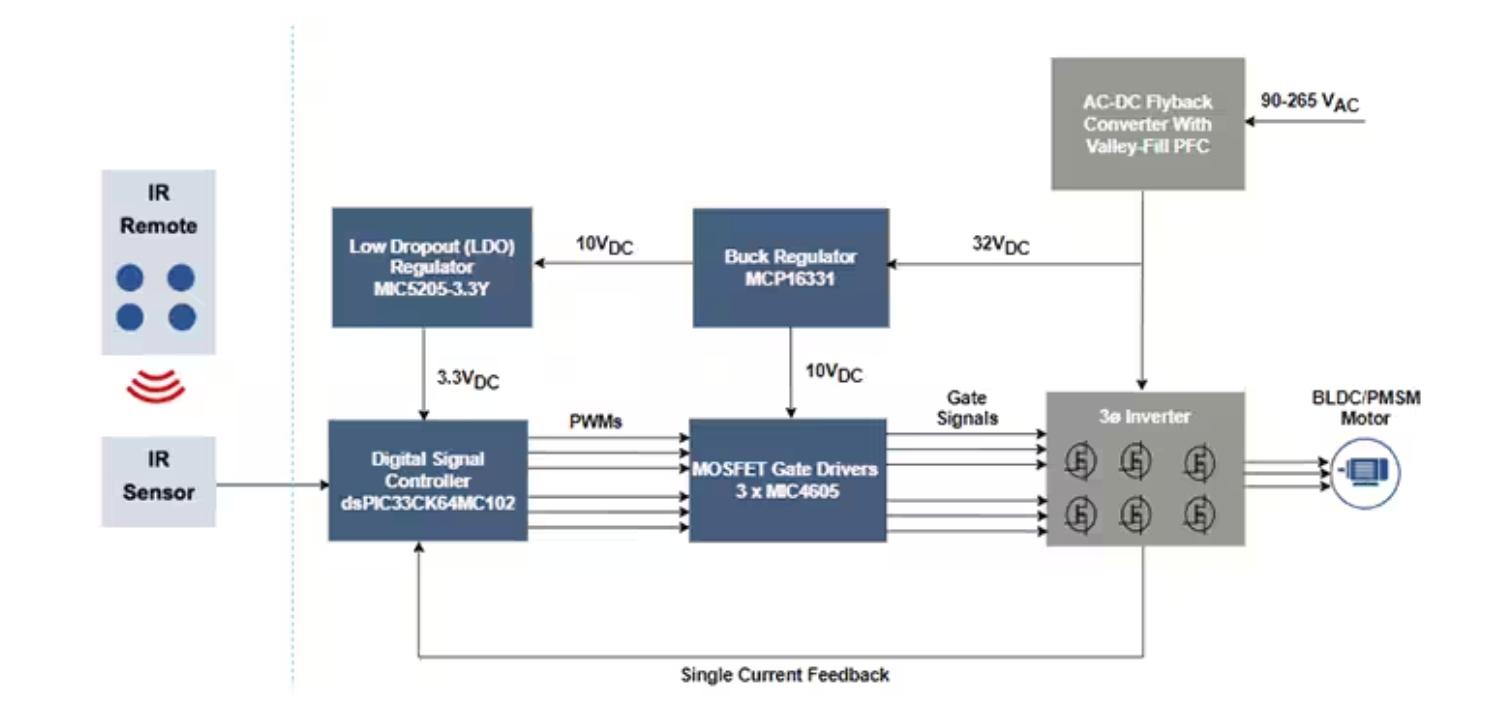

Changing from a high-voltage, single-phase ACIM to a lower-voltage three-phase PMSM/BLDC motor requires a two-stage power conversion circuit. First, a fly-back rectification circuit converts the 90−265 VAC input power into an intermediate DC voltage. This voltage is used to spin a BLDC or PMSM motor, so it should be in a voltage range that matches the intended motor. In our ceiling fan reference design, the intermediate voltage is set to 32 volts.

It’s also important that the fly-back circuit keep a high Power Factor Correction (PFC) ratio. Even during low fan speed conditions, our reference design keeps the PFC at 0.9 or above. Doing this reduces the load on the power delivery system and avoids penalties or extra charges that could apply if the PFC drops below that.

The intermediate 32 volts are then dropped to 10 volts by an MCP16331 peak current mode PWM DC/DC converter. This is used to efficiently power the three MIC4605 half-bridge MOSFET gate drivers, which switch the six MOSFETs on and off as directed by a dsPIC® Digital Signal Controller (DSC) PWM outputs. The 10 volts are further dropped to 3.3V by a highly efficient MIC5205 Low Drop-Out (LDO) voltage regulator to power the dsPIC DSC motor controller itself.

The components for the reference design were chosen to optimize the Bill of Materials (BOM) for the minimum number of components and to achieve the lowest cost. For example, the highly integrated dsPIC33CK64MC102 DSC includes two operational amplifiers (op amps) for motor phase current amplification and a comparator for detecting an over-current condition, saving both the space and cost of using external circuits. Instead of dual- or triple-shunt motor phase current measurement circuits, a single current implementation is used to further reduce cost and space. The resulting compact, round 10 cm diameter board fits into the top of a typical fan motor, resembling an actual end-product solution. The BOM is also China RoHS 50- and EU Reach-compliant.

In order to obtain the highest energy efficiency, the maximum motor torque output and quiet operation, the dsPIC DSC runs an advanced Field Oriented Control (FOC) algorithm with sinusoidal PWM outputs. An Initial Position Detection (IPD) software algorithm ensures the correct direction of fan movement on startup. Flying start and braking algorithms provide smooth restarts when the fan is windmilling or if a fan direction change is required.

Supporting further customization, four General Purpose Input/Output (GPIO) pins are brought out to the edge of the board. These pins can be configured by software as a Universal Asynchronous Receiver-Transmitter (UART) or Serial Peripheral Interface (SPI) or for input capture functionality. This allows the user to create an interface to a wide range of sensors or communication protocols such as Infrared (IR), Bluetooth®, Wi-Fi® or a propriety home automation protocol.

This low-voltage ceiling fan reference design provides a fan solution optimized for energy efficiency. You can run the ceiling fan at 300 RPM and only draw ~17.5W, about the same amount of power that two LED (60W-equivalent) bulbs require. With this reference design used as a starting point, creating an ideal fan solution can be realized with a very short time to market.