News Centerposition:Baoxingwei > News Center > 正文

Developing a Peltier Cooled Metal Plate with a PIC16F17146

Edit:Baoxingwei Technology | Time:2023-02-24 16:39 | Number of views:332

A Peltier Cooled Metal Plate can be implemented with a smaller Bill of Materials (BOM) by utilizing the Core Independent Peripherals (CIPs) of a PIC16F17146.

Introduction to Developing a Peltier Cooled Metal Plate With a PIC16F17146

Blocks of specialized hardware called Core Independent Peripherals (CIPs), which are integrated into microcontrollers (MCUs), can lower power consumption, increase CPU efficiency, and introduce new MCU capabilities. A good example of the efficacy of CIPs in use is the Peltier Cooled Metal Plate, also known as the Cold Plate. Due to the high degree of integration made possible by CIPs, the Bill of Materials (BOM) for this application is kept to a minimum.

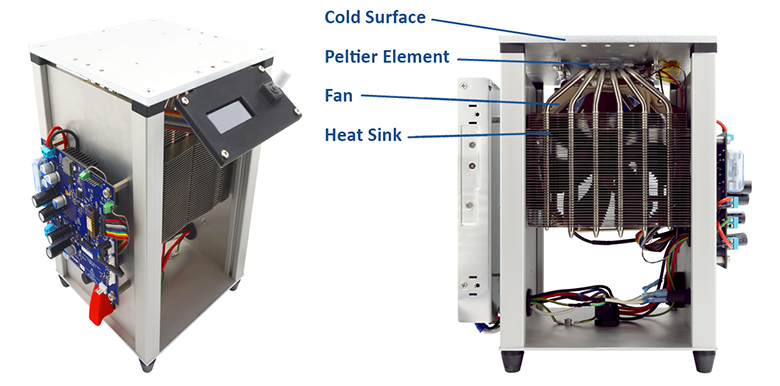

The goal of this application, as its name implies, is to cool the top metal surface to a temperature that the user specifies. In order to accomplish this, heat is transferred from the upper plate into the heatsink below using a Peltier element (solid-state heat pump). The heat is then dispersed into the atmosphere by a cooling fan connected to the heatsink. The demo is constructed in Figure 1.

Figure 1 – Assembled Cold Plate

The MCU performs the following operations:

Signals when the Peltier should be on and when it should be off

Calculates the temperature at the cold plate and heat sink using Negative Temperature Coefficient (NTC) thermistors

Amplifies the current sense output from the Peltier circuit

Maintains safe operation outside of the lab environment

Verifies the cooling fan is operating

Monitors the system for abnormal values (Peltier current and temperature)

Resets if self-check is not completed

Validates loaded user settings

Displays telemetry on the user interface

Responds to inputs from the user (pushbutton and rotary encoder)

Changes the LED light patterns as the system is running

This seems like a lot of work for a single 8-bit MCU to perform. But using CIPs, these functions and tasks can be accomplished. To implement this design, the PIC16F17146 MCU was selected due to the analog peripherals. This family of MCUs is analog focused with peripherals such as a 12-bit differential Analog-to-Digital Converter with Computation (ADCC), an integrated operational amplifier (OPAMP) two analog comparators (CMP) and two Digital-to-Analog Converters (DACs).

These analog peripherals allow the design to be almost entirely implemented in the MCU. An example of this is the current sense amplifier that uses the OPAMP. As the Peltier element pulls current, a voltage is generated across a current-sense resistor on the low-side. Since the voltage induced is relatively small (100 mV at 10A), it would be difficult to use the other analog peripherals with this signal directly. By using the OPAMP as a current sense amplifier (Figure 2), the magnified signal can be used with the other analog peripherals, which increases their analog performance.

Figure 2 – Current Sense Amplifier (Shown with Current Monitoring System)

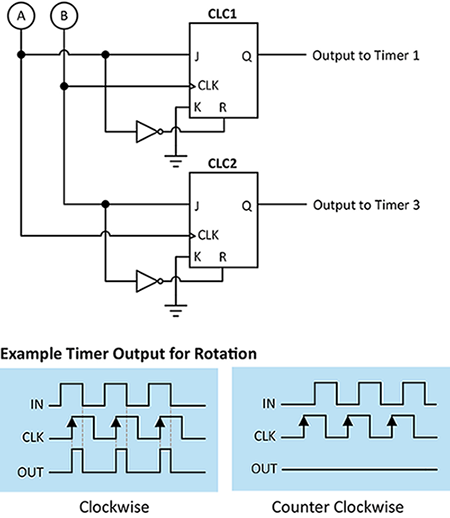

A quadrature decoder for the user interface was another function added with CIPs. To browse menus and change the Cold Plate's settings, the user rotates the encoder. Two square waveforms that are 90 degrees out of phase with one another make up the quadrature encoded waveform that is produced by the rotary encoders. Depending on which of the waveforms leads while the other lags, the rotation's direction will be decided. This is demonstrated in Figure 3.

To convert the quadrature encoded signal into rotation, two Configurable Logic Cells (CLCs) are used to convert the quadrature encoded signal into clockwise and counterclockwise pulses, which is then fed into Timer 1 and Timer 3, which act as counters. From there, the CPU can perform simple arithmetic on the Timer counts to determine the net change since the last read, which correlates with the encoder movement by the user. This minimizes the amount of computation time the CPU must use to determine the net rotation since the last read.

Figure 3 – Implementation of a Quadrature Decoder

A big concern during development was ensuring this application could be run outside of the lab environment. The Peltier circuit draws substantial amounts of current while generating extreme (hot/cold) temperatures. Functional Safety (FuSa) ready peripherals on the PIC16F17146 were used to harden the system against software faults that could occur.

While the Peltier is running, the microcontroller performs a periodic self-check to monitor the Peltier current, system temperatures and cooling fan speed to ensure everything is operating within expected parameters. For instance, if the cooling fan stopped running, the system should immediately shut down to prevent damage to the Peltier element. Likewise, if the Peltier failed short, the system should immediately power down. This periodic self-check is enforced by the Windowed Watchdog Timer (WWDT). If the self-check fails to run, the microcontroller will reset.

Another safety feature implemented was a Cyclic Redundancy Check (CRC) of the user settings. User settings such as the target temperature, units and hysteresis parameters are stored in device EEPROM. A checksum is also incorporated into the EEPROM to verify the memory was not corrupted. On startup, the system examines the EEPROM to see if the settings are present and then valid. If the memory fails validation, the settings are erased and set to compile-time defaults.

Some of the advantages and applications of CIPs for implementing highly integrated systems that can lower your BOM have been covered in this blog article. While it would be impossible to cover every CIP implementation used inside of the Cold Plate in a blog post, the application note that goes along with it does so in greater depth. On Microchip, you can also see the device instructions and source code.